Bullivants HMPE Hose Restraint

Product Spotlight

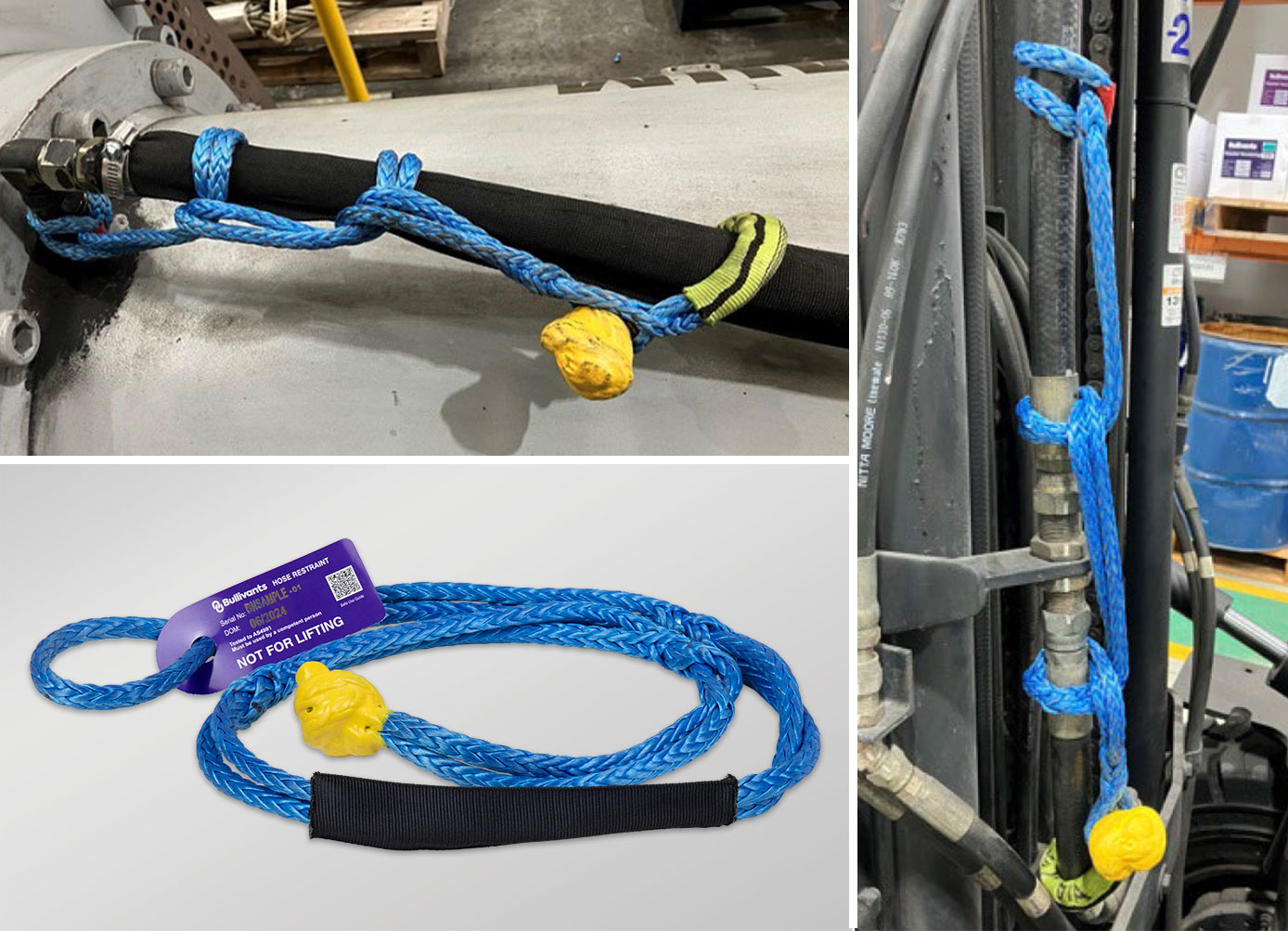

The Safer Hose Restraint Solution

Engineering a Smarter Way Forward

In industries where high-pressure hose systems are critical, safety and efficiency must go hand in hand. For one customer, traditional wire rope restraints were no longer meeting operational demands. The process of disconnecting hoses, isolating equipment, and issuing permits had become time-consuming and physically demanding. They turned to Bullivants to help engineer a smarter, safer solution.

Moving Beyond Wire Rope Restraints

While wire rope restraints had served their purpose, replacing them involved multiple steps that disrupted operations:

- Disconnecting hoses

- Isolating equipment

- Issuing permits

- Manually dismantling fittings

This led to extended downtime and increased manual handling. The customer needed a solution that simplified installation, reduced physical strain, and aligned with stringent safety standards.

A New Approach to Hose Restraint

Bullivants conducted a thorough review of hose types, pressure ratings, and site conditions before designing a restraint system that could be installed externally without disconnecting the hose. The team selected AmSteel® Blue made with Dyneema® fibre, known for its exceptional strength, flexibility, and lightweight handling.

The new restraint system featured:

- Spliced soft eyes for ergonomic handling

- Certification to AS 4991 and NATA ISO 17025 standards

- Simple installation using firm hand tension, soft shackles, and choke hitches

- Proven strength exceeding 130kN through destructive and cyclic testing

Designed with the User in Mind

Bullivants collaborated closely with site teams throughout development, refining the design based on real-world feedback. Practical enhancements included:

- Larger soft eyes for easier grip

- Repositioned tags for better visibility

- Colour-coded knots for quick identification

- QR codes linking to installation and inspection guides

Results: What the Customer Experienced

The transition to Bullivants’ hose restraint system delivered a range of measurable benefits. Manual handling risks were significantly reduced, and changeouts that previously took hours could now be completed in minutes. The ergonomic design simplified installation and minimised physical strain, while the system’s high pressure and temperature resistance ensured reliable performance in demanding environments. Clear identification and traceability were achieved through colour-coded knots and repositioned tags, and the low-maintenance design offered long-term durability. Productivity improved as the restraints could be fitted to existing hoses without the need for disconnection, and the system was available in three major size ranges to suit varied applications. The use of HMPE rope eliminated hazards associated with rust and broken wires, enhancing safety and ease of handling. Certified to AS 4991 and issued with NATA test certificates, the solution was backed by local capability, support within three hours to any site and a robust inventory management system already in place. One team member, with over 40 years of experience, described the change as “life-changing.”

Delivered with Confidence

The customer chose Bullivants for their long-standing relationship, deep understanding of operational needs, and ability to respond quickly. With inventory management and local support already in place, the solution was delivered efficiently and aligned with business goals.

The hose restraint system is now in full use across a range of applications including:

- Drilling

- Pipelines

- Roof support

- Water piping

Supporting Long-Term Safety

Bullivants continues to support the rollout with on-site training, monitoring, and regular inspection reviews ensuring the system remains safe, reliable, and fit for purpose for years to come.

Looking to improve safety and efficiency in your hose restraint systems?

Contact Bullivants now to learn more.